Advantages of Resistance Welding

Ad Plasma Table CNC Plasma System PT Cutmaster PT-510HD PT-44. The wastage of the metal is very little in the case of resistance.

Resistance Welding Rw Substech

It is a fast process.

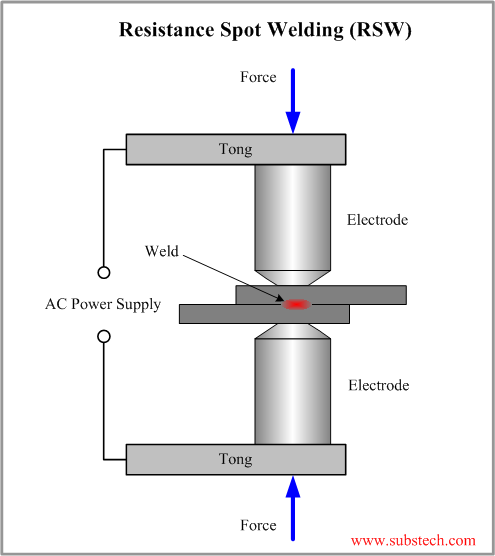

. Resistance welding is the joining of metals by applying pressure and passing current for a length of time through the metal area which is to be joined. 4 simple operation easy to implement mechanization and automation improved working conditions. No filler metal is required.

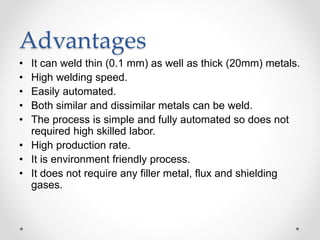

The Advantages of Resistance Welding It is a simple method that does not require an expert to weld Welders can use this method to weld both similar and dissimilar metals. Spot welding can be easily automated and is extensively in the automotive industry for the production of car chassis parts and other sizable components. Projection welding is actually a modification of spot welding the pioneer resistance welding process.

From novice to professional welders rest assured that if you want it we have it. When the molten core is formed it is always surrounded by a plastic ring and the molten metal is isolated from the air so the. The advantages disadvantages of resistance welding include the following Advantages This method is simple and does not necessary high expert labor.

The heating of the workpiece is. Immediate Online Ordering Ready to Ship. Projection welding is generally used for projects with thicker materials around 0035.

One of the main advantages of this type of. The advantages of resistance welding 1 nugget always by the plastic ring molten metal and air separation metallurgical process is simple. The resistance welding process does not require high temperatures and hence it allows for the welding of soft materials such as copper.

Ad Search and Buy AWS Publications. The key advantage of resistance welding. In the last session we had discussed the gas welding process and arc welding process and whereas in todays session we will discuss Resistance Spot Welding along with its Definition.

Advantages of Resistance welding. Resistance spot welding is one of them. Advantages of the electric resistance welding.

Department of Energys Office of Scientific and Technical Information. Ad Bakers Gas offers everything you need for your welding needs. The resistance welding metal.

5 high productivity and no noise and harmful gases in mass production. It is a very economical process because there are no consumables used in this process so environment-friendly too. Similar and dissimilar metals can be welded.

Advantages of resistance welding. Various pressure welding processes are used in the welding industry. This blogpost explains the process of resistance spot welding its advantages.

The advantages of the resistance welding are list as follows It is a faster method of welding of two pieces. Resistance welding refers to the joining of two pieces of metal by applying pressure and heat to weld electrodes creating a welded joint. 2 heating time is short concentrated.

Following are the advantages of resistance welding. It can weld both the thin 01 mm and thick 20. Spot welding is also used in the.

Resistance welding is a type of electric welding in which heat produced to weld the two metal pieces will be due to the resistance offered to the flow of current by the two metal.

Resistance Welding Principle Types Application Advantages And Disadvantages Mech4study

You Need To Know About Resistance Welding Part 3 It S Type Advantages And Disadvantages Api Cswip Qaqc Level Ii Iii Hvac Fire Fighter Courses By Andt Advanced Institute Of Nondestructive Testing

Resistance Welding Conti Resistance Welding Is A Welding Process In Which Work Pieces Are Welded Due To A Combination Of A Pressure Applied To Them Ppt Download

Resistance Welding Principle Types Application Advantages And Disadvantages Mech4study

5 Different Types Of Resistance Welding With Diagram Pdf

0 Response to "Advantages of Resistance Welding"

Post a Comment